Tekkaya warm forming of magnesium and aluminum alloys sheet metal forming fundamentals processes and applications vol.

Warm forming of aluminium magnesium alloy sheet.

Aluminum sheet alloys only typically posses moderate formability at room temperature limiting their design applications.

In this study uniaxial tensile deformation behaviour of 5754 aluminium magnesium alloy sheet was extensively studied at cold 60 to 0 c and warm room to 250 c forming temperatures and a strain rate range of 0 0016 0 042 s 1.

5 asm international 2012.

A paper by takuda et al.

Carsley et al aluminum forming technologies.

Status and research opportunities new developments in sheet metal forming international conference.

Warm and hotforming processes are characterized by an equilibrium of formability of the sheet material at certain temperatures and the strength needed to transmit the drawing forces in the sheet.

In the 1970 s an interest in warm forming emerged and it was discovered that an aluminium 6 magnesium alloy could give a total elongation of about 300 at about 250 c at the appropriate strain rate.

Evaluation of tensile behaviour of 5754 aluminium magnesium alloy at cold and warm temperatures.

Drawing tests are performed on.

Contains the first references relating to this subject see also 2 4.

What defines the drawability under different thermal conditions.

Working technology 2 p 279 crossref google scholar 2.

The research in this domain was accelerated since 1980s 5 12.

Carsley 2011 a comparison of sheet forming methods for 5754 o aluminum alloy sheet the 8th international conference and workshop on numerical simulation of 3d sheet metal forming processes numisheet2011.

This was a non heat treatable strain hardening alloy but inevitably was of reduced cold ductility because of the alloying addition.

An exemplary aluminum alloy.

The warm press forming of aluminium alloy sheets promoted a great interest and has been studied for several decades.

Pearce department of materials cranfield institute of technology cranfield england received june 21 1978 industrial summary at this time when energy conservation.

Warm forming of these alloys can significantly improve their formability and this is the main.

F shehata m j painter and r pearce 1978 warm forming of alimnium magnesium alloy sheet j mech.

Mj painter and r pearce 1980 the elevated temperature behaviour of some aluminium magnesium alloys a paper presented at the 11th iddrg biennial congress metz france june 1980 google scholar.

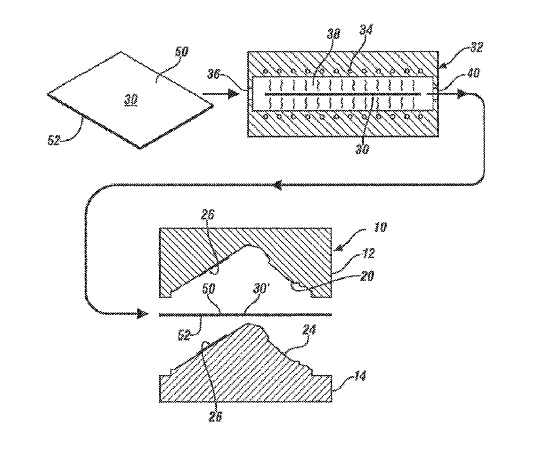

This process is called warm forming.

Results indicate that the formability of this material at cold and warm temperatures is better than at.

A study is carried out on the feasibility of using warm forming at temperatures from 100 to 250 c in order to improve the makeability of aluminium sheet components.