Unlike abrasive waterjet cutting however only pure waterjet is used to cut plastics and acrylics.

Water jet cutting thin glass.

Cutting glass with waterjet.

Cutting and piercing glass is not a problem with flow waterjet technology.

Waterjet machines cut all types of metals.

Cutting with a waterjet produces a smooth edge with no burn marks cracking or excess burrs.

Pure waterjet is used for cutting softer materials including gasket foam food paper plastic and carpet.

In fact this process supersedes the development of the abrasive waterjet used to cut harder materials such as stone glass and metals.

In thin sheets of glass it may be necessary to slow down the cutting head to avoid adding excess vertical pressure to the sheet.

In addition since waterjet is a cold cutting method there are no heat affected.

From cutting of intricate stained glass to piercing holes in glass to easily cutting laminated ballistic glass users from a variety of industries have discovered the versatility and cost effectiveness of cutting glass materials with waterjet technology.

Be sure to include a controlled lead out every time a cut is closed or the cut leads off the edge of the workpiece.

The clean very thin waterjet stream thinner than a strand of human hair does not cause the material being.

The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite while the terms pure waterjet and.

Waterjet abrasives are typically made of garnet with grit size ranging from 50 to 220 mesh though 80 is the most common.

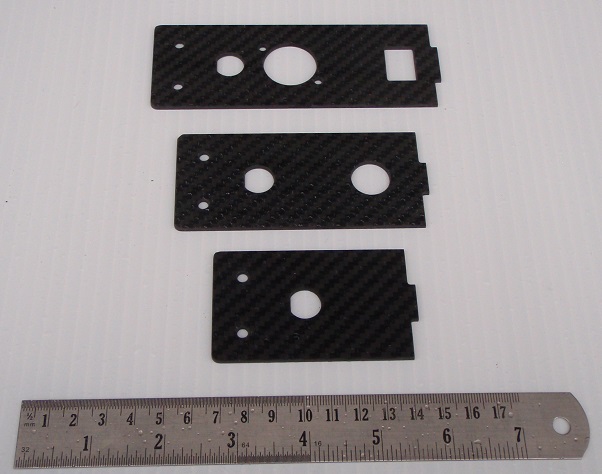

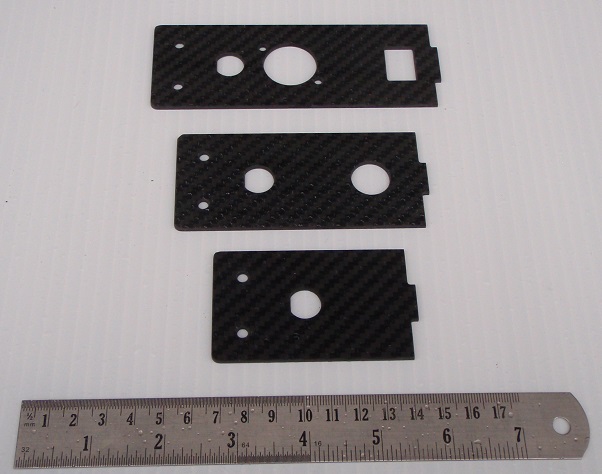

Omax abrasive waterjets are used to cut a wide variety of glass products from ultra thin smartphone panels to thick multi layered bullet proof panels for vehicles to panels for stained glass windows.

A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using an extremely high pressure jet of water or a mixture of water and an abrasive substance.

Abrasive waterjet is used to cut harder materials such as metal ceramic stone wood and glass.

You may find that higher mesh sizes 100 120 or 150 at a flow rate of about 0 4 lbs 0 2 kg per minute give smoother results with less microchipping on the edges.